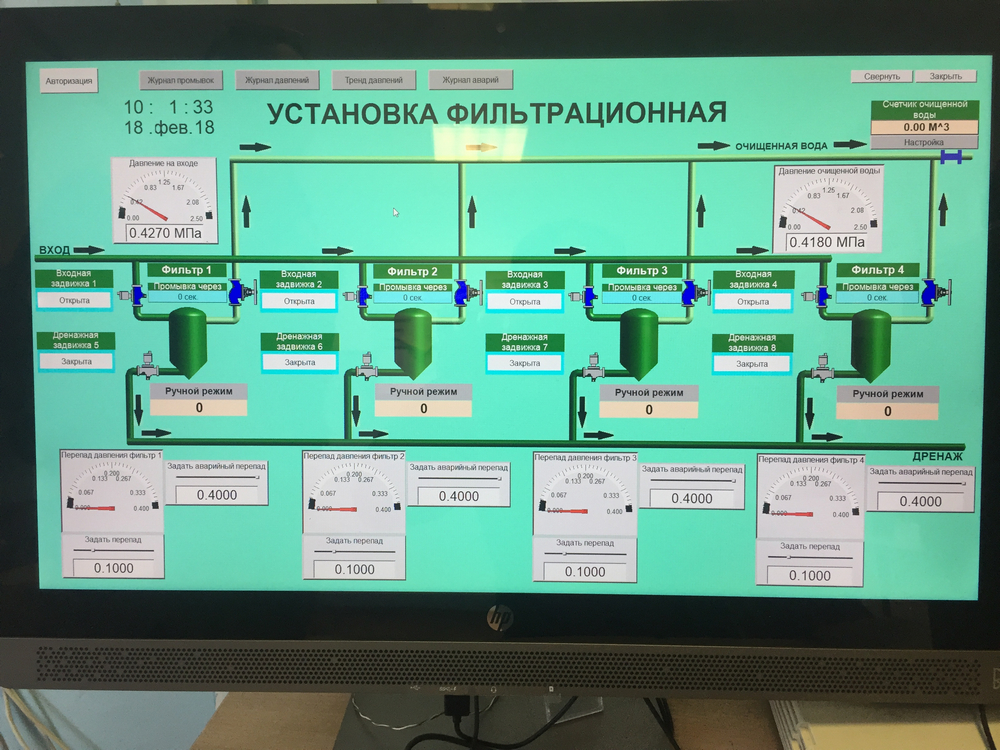

Automated technological filtering unit based on the principles of artificial intelligence (BTF), is designed to purify liquids, gas and gas condensate from mechanical impurities and produced water in order to protect the components of the technological system from mechanical wear and pollution. It is operated at gas, oil and related industries.

Automated technological filtering unit based on the principles of artificial intelligence (BTF), is designed to purify liquids, gas and gas condensate from mechanical impurities and produced water in order to protect the components of the technological system from mechanical wear and pollution. It is operated at gas, oil and related industries.

BTFs are equipped with booster pumps to increase the pressure at the inlet to the FGK filter.

Main parameters and characteristics of BTF

|

№ |

Name of indicator |

Indicator value |

|

1. |

Working environment |

Liquid gas |

|

2. |

Transport hazard class |

1, 2, 3 according to GOST 12.1.007 |

|

3. |

The temperature of the liquid at the inlet to the filters, 0 C |

0-320 |

|

4. |

Productivity, m3 / h |

10-10000 |

|

5. |

Working pressure, MPa (kgf / cm²) |

1.6 (16) ÷ 21.0 (210) |

|

6. |

Installation mode |

continuous |

|

7. |

Nominal filtration fineness, microns (mm) |

1.0 (0.001) - 4000 (4.0) |

|

8. |

Block Box Explosion and Fire Category |

D, A, B-1a, B-1g, P-1 |

|

9. |

Lower operating temperature limit during operation, ° С |

- 60 |

|

10. |

Upper operating temperature limit during operation, ° С |

+55 |

|

11. |

The upper value of relative humidity at a temperature of 25 ° C,% |

98 |

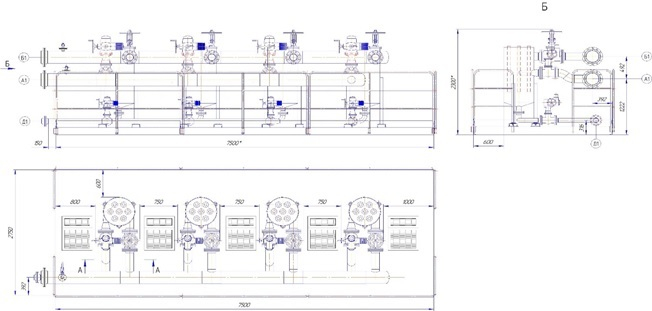

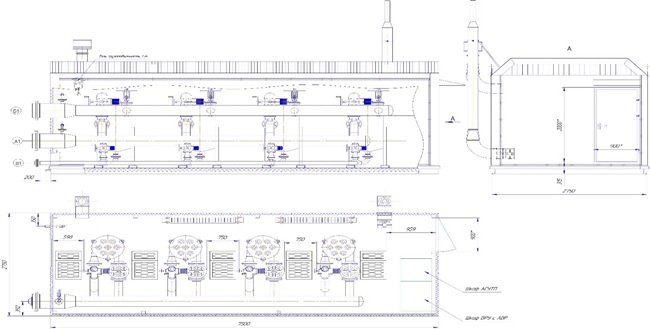

The BTF design provides for two types:

type 1 - open type unit (on the frame, platform);

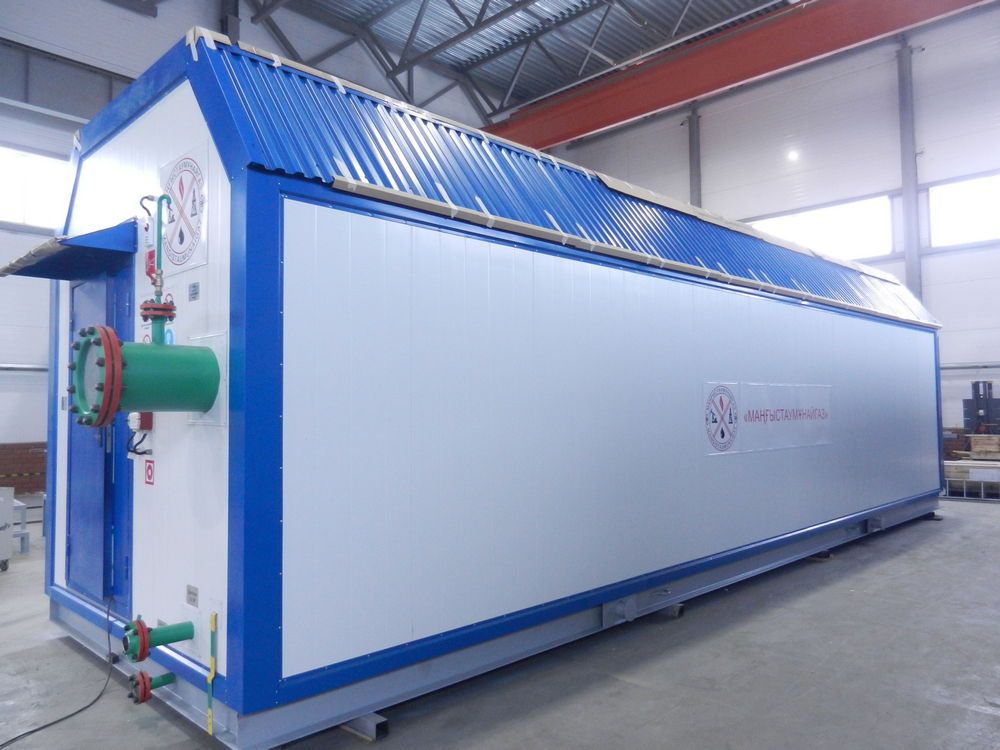

type 2 - closed type block (in a block box, container, etc.)

Additional information on BTF:

1. The performance of BTF filters depends on the cell size of the filter element filters (filter fineness). The nominal filtration fineness is specified when ordering BTF, based on the conditions and parameters of the working medium, taking into account the maximum allowable pressure drop across the filter, with the provision of particle size analysis of mechanical impurities in liquid, gas and gas condensate to BTF.

2. For effective cleaning of the FGK filter cartridges by the backwash method, the drain line of the filter must be connected to the drain tank (internal overpressure in the tank

0 MPa).

3. When cleaning liquids with a filter fineness from 1 μm (0.001 mm) to 100 μm (0.1 mm), oil products should not be present.

The design and manufacture of BTF is carried out taking into account the parameters of the pumped medium, the required productivity and pressure, the nominal fineness of filtration, operating conditions and individual customer requirements.